F1 Boring Head

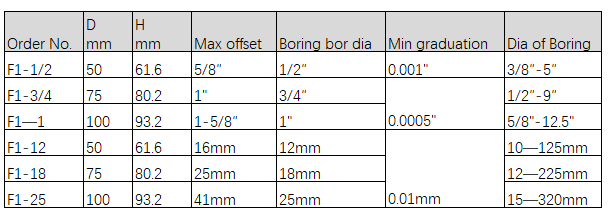

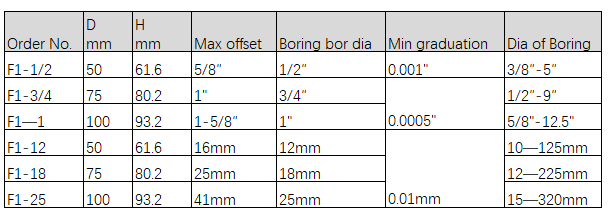

RuiHan, a leading Chinese manufacturer of mold clamps, offers high-precision F1 boring heads available in 1/2″, 3/4″, 2″, 3″, and 4″ sizes for mills. In addition, we provide injection mold components, die press parts, machine tools, and fasteners tailored to your needs. For detailed specifications, pricing, and inventory of our F1 boring heads—or to inquire about any other machine tools—please contact the RuiHan sales team.

A boring head is a cutting tool used in machining operations to enlarge or refine existing holes in a workpiece. It typically consists of a body that holds one or more cutting tools, called boring bars, which extend outward from the head at different angles.

The boring head is mounted on a milling machine or lathe and is rotated along with the workpiece. The boring bar is then moved longitudinally into the hole, gradually removing material and enlarging the diameter of the hole.

Boring heads come in various sizes and configurations depending on the specific application. Some models allow for micro-adjustments to achieve precise hole diameters, while others have interchangeable boring bars to accommodate different hole sizes.

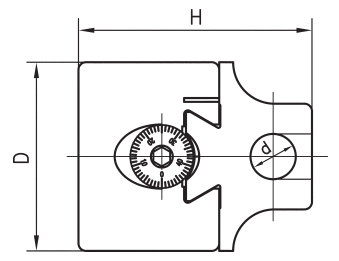

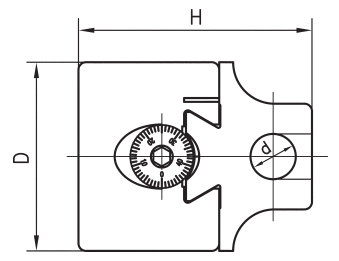

F1 Boring head

There are several types of boring heads, including:

1.Offset Boring Head: This type of boring head features an off-center position for the boring bar, allowing for the creation of holes of varying diameters.

2.Universal Boring Head: This head allows for the boring bar to be set at different angles, making it suitable for creating angled holes.

3.Rough Boring Head: As the name suggests, this head is designed for rough machining applications where material removal is the primary objective.

4.Finish Boring Head: This head is used for finishing operations where achieving a high degree of accuracy and surface finish is critical.

In addition to boring heads, other related tools used in boring operations include boring bars, drill bits, reamers, and adjustable boring cartridges.

Universal boring head F1 – Precision and Versatility with F1 Boring head

F1 Boring head provided by RuiHan stands as a hallmark of precision in machining, offering unmatched accuracy and flexibility right from the start. This product description explains the features, advantages, and applications of the F1 Boring head, ensuring top-notch performance in demanding operations.

The F1 Boring head is a precision tool designed for milling machines to enlarge or refine pre-existing holes with exceptional accuracy. Mounted onto the machine spindle, this tool securely holds replaceable boring bars via an adjustable dovetail slide mechanism. This design enables micro-adjustments for precise cutting diameters, making the F1 Boring head ideal for tight-tolerance machining.

Key Features

Adjustable Dovetail Slide:

A finely controlled slide mechanism with a precision screw and dial allows for micro-adjustments of the boring bar’s offset, ensuring exact hole dimensions.

Solid Carbide Boring Bars:

The cutting tools are made of solid carbide, providing excellent rigidity and wear resistance for consistent performance.

Multiple Tool Mounting Points:

Three mounting holes allow for different boring bars to be used, adding versatility in handling various hole sizes and materials.

Locking Mechanism:

Secure Allen set screws lock both the dovetail slide and the boring bars in place, minimizing vibration and maintaining positional stability during operation.

Advantages of the F1 Boring head

The F1 Boring head is engineered for high precision and superior surface finish. Its design allows for achieving tight tolerances (e.g., ±0.0005 inches), which is critical in applications like bearing pockets. Additionally, this tool minimizes the need for secondary operations such as reaming, thereby enhancing overall cost efficiency and reducing machining time.

Applications

The F1 Boring head finds extensive use in various high-precision machining scenarios, including:

Bearing Pockets:

For machining precise bores where accuracy and superior surface finish are critical.

Engine Components:

Ideal for cylinder liners, valve seats, and other high-tolerance automotive parts.

Aerospace Parts:

Used in flange bores or housings that demand strict adherence to specifications.

Tool and Die Making:

Perfect for producing jigs, fixtures, and molds with accurately aligned holes.

Additionally, the Universal boring head F1 variant may incorporate enhanced features such as digital adjustment systems for faster setup and reduced trial-and-error adjustments, ensuring it meets the evolving needs of modern machining.

The RuiHan F1 Boring head delivers precision, versatility, and exceptional performance for a wide range of machining applications. Whether it is enlarging pre-existing holes or refining them to meet tight tolerances, the F1 Boring head remains a trusted tool in high-precision environments. Embrace the reliability and advanced design of the F1 Boring head to achieve outstanding machining results.