Morse taper sleeves, also known as Morse taper adapters or Morse taper reducers, are mechanical components used in machining and tooling applications. They are used to connect tools with different Morse tapers to allow for the use of tools with different shank sizes or Morse taper sizes in a machine spindle or tailstock.

Morse taper sleeves are commonly used in metalworking, woodworking, and other precision machining applications where accurate tool alignment and secure tool holding are critical for achieving precise and consistent results.

Our high-quality Morse taper sleeves, also known as Morse taper adapters or Morse taper reducers, designed for use in precision machining applications. Our Morse taper sleeves are essential components for connecting tools with different Morse tapers, allowing for versatile tooling options in machine spindles or tailstocks.

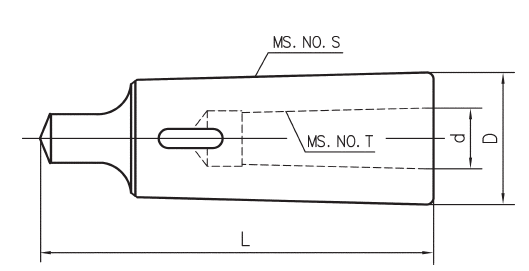

Morse taper sleeves typically have a tapered shape with one end having a larger Morse taper size, which is inserted into the machine spindle or tailstock, and the other end having a smaller Morse taper size, which accepts the tool with the corresponding Morse taper size. They are commonly used in drill presses, lathes, milling machines, and other machining equipment.

Morse taper sleeves are designed to provide a precise and secure connection between the machine spindle or tailstock and the tool, ensuring accurate alignment and smooth rotation. They are made from high-quality materials, such as hardened steel, to provide durability and withstand the high forces and speeds encountered during machining operations.

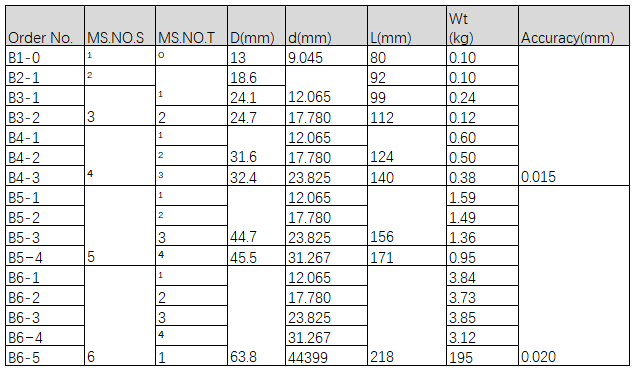

There are various sizes and types of Morse taper sleeves available, ranging from Morse taper #0 to Morse taper #7, with different taper angles and lengths to accommodate different tooling requirements. It is important to select the correct Morse taper sleeve that matches the Morse taper size of the tool and the machine spindle or tailstock to ensure proper fit and function.

DIN2185 Morse Taper Sleeves

◆Reliable and Precise Connection: Our Morse taper sleeves are manufactured from hardened steel, ensuring durability and providing a precise and secure connection between the machine spindle or tailstock and the tool. This ensures accurate alignment and smooth rotation during machining operations, resulting in consistent and high-quality results.

◆Wide Range of Sizes and Types: We offer a wide range of Morse taper sleeves to accommodate different tooling requirements. Our product line includes Morse taper #0 to Morse taper #7, with taper angles of 1:10, and lengths ranging from 63mm to 349mm. This allows for compatibility with various drill presses, lathes, milling machines, and other machining equipment.

◆Versatile Applications: Our Morse taper sleeves are suitable for use in metalworking, woodworking, and other precision machining applications where precise tool alignment and secure tool holding are critical. They are commonly used in drilling, turning, milling, and other machining operations, providing reliable and efficient tooling options.

◆Ease of Use: Our Morse taper sleeves are designed for easy installation and removal, making tool changes quick and hassle-free. They are compatible with standard Morse taper sizes and can be easily inserted into machine spindles or tailstocks, saving time and effort during machining operations.

◆Trusted Quality: Our Morse taper sleeves are manufactured to high-quality standards, ensuring consistent performance and long-lasting durability. They are designed to withstand the high forces and speeds encountered during machining operations, providing reliable and safe tool holding options.

◆Application-specific Options: We understand that different machining applications may have unique requirements, and we can also provide custom Morse taper sleeves tailored to your specific needs. Our team of experts can work with you to design and manufacture Morse taper sleeves with specific taper angles, lengths, or other specifications to meet your machining requirements.

| Morse Taper Size | Taper Angle | Length (mm) | Common Use |

| Morse Taper #0 | 1:10 | 63 | Small-sized drill presses, lathe tailstocks |

| Morse Taper #1 | 1:10 | 85 | Drill presses, lathe tailstocks, milling machines |

| Morse Taper #2 | 1:10 | 112 | Drill presses, lathe spindles, milling machines |

| Morse Taper #3 | 1:10 | 139 | Lathe spindles, milling machines, heavy-duty drilling |

| Morse Taper #4 | 1:10 | 175 | Lathe spindles, milling machines, heavy-duty drilling |

| Morse Taper #5 | 1:10 | 222 | Large-sized lathes, milling machines, heavy-duty drilling |

| Morse Taper #6 | 1:10 | 279 | Large-sized lathes, milling machines, heavy-duty drilling |

| Morse Taper #7 | 1:10 | 349 | Large-sized lathes, milling machines, heavy-duty drilling |

Note: The taper angle for all Morse tapers is 1:10, which means that the diameter reduces by 1 unit for every 10 units of length along the taper.

Morse taper sleeves are available in various lengths, typically ranging from around 63mm to 349mm, although longer custom sizes may also be available. The lengths mentioned in the table are approximate and may vary depending on the manufacturer and specific model.

It's important to choose the correct Morse taper sleeve that matches the Morse taper size of your tool and the machine spindle or tailstock to ensure a proper fit and safe operation. Using the wrong size can result in misalignment, poor tool holding, and potential damage to the tool or the machine. Always refer to the manufacturer's specifications and guidelines for proper selection and use of Morse taper sleeves in your specific machining application.

RIEHOR Morse taper sleeves are reliable, precise, and versatile components for precision machining applications. With a wide range of sizes and types, ease of use, and trusted quality, our Morse taper sleeves are the ideal tooling solution for connecting tools with different Morse tapers, ensuring accurate alignment and consistent results in your machining operations. Contact us to learn more about our Morse taper sleeves and how they can enhance your machining processes.