A Handy Tool for ER Collets

In the world of CNC machining and tool holding, the ER wrench plays a crucial role in the proper installation and tightening of ER collets. This specialized wrench is designed to provide a secure grip and facilitate the efficient handling of ER collets.

An ER wrench is a tool specifically designed to tighten and loosen ER collets. It typically features a T-shaped handle with a hexagonal opening at one end. The hexagonal opening corresponds to the size of the ER collet nut, allowing the wrench to securely engage with the nut for tightening or loosening purposes.

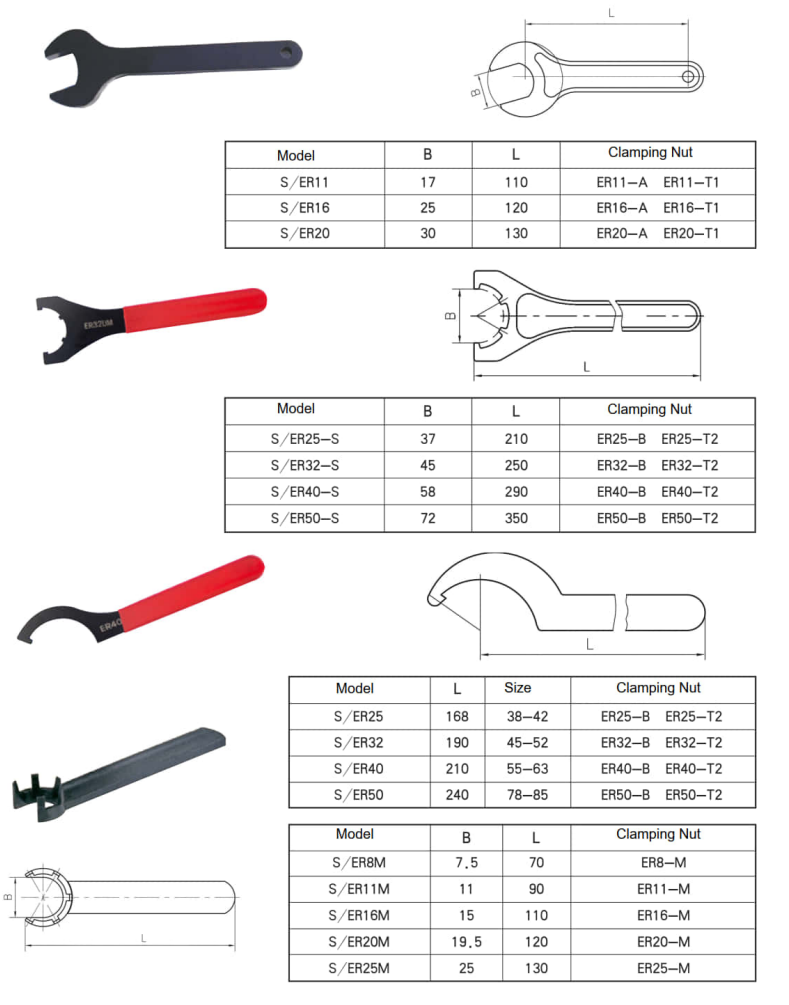

An ER wrench is a tool used for tightening and loosening the collets in an ER collet chuck. The ER wrench comes in different sizes to match the various collet types used with ER chucks, such as ER11, ER16, ER20, ER25, and so on.

The ER wrench typically has a long, slender body with a hexagonal end that fits into the collet nut of an ER collet chuck. The other end of the wrench may have a knurled or textured grip for easier handling, and some models may also feature a spring-loaded ball bearing to help keep the wrench securely in place during use.

Using an ER wrench is straightforward: simply insert the hexagonal end of the wrench into the collet nut and turn it clockwise to tighten or counterclockwise to loosen. It's important to use an appropriate-sized wrench for the collet being used to avoid damaging the chuck or collet.

The ER wrench is an essential tool for anyone working with an ER collet chuck, as it allows for easy and precise adjustment of the collets for accurate machining.

The ER wrench offers several features and benefits that contribute to its indispensability in the CNC machining process.

Comfortable Grip: The T-shaped handle of the ER wrench provides a comfortable grip, allowing machinists to exert the necessary force for tightening or loosening ER collet nuts without straining their hands.

Hexagonal Opening: The hexagonal opening at the end of the wrench ensures a precise fit with the nut of the ER collet. This design feature prevents slipping or stripping of the nut during tightening or loosening, ensuring a secure connection between the collet and the tool.

Durable Construction: ER wrenches are typically made from high-quality materials such as hardened steel or alloy, ensuring durability and longevity. This robust construction allows them to withstand the rigors of the machining environment and repetitive use.

Ease of Use: ER wrenches are lightweight and easy to handle, making them convenient to use during tool changes. Machinists can quickly tighten or loosen the collet nuts, minimizing downtime and improving overall efficiency in the machining process.

Compatibility: ER wrenches are designed to match the specific size of ER collet nuts, ensuring compatibility and proper engagement. They are available in various sizes to accommodate different ER collet types, such as ER16, ER20, ER32, and more.

Using an ER wrench is a straightforward process. Here are the general steps for tightening or loosening an ER collet using an ER wrench:

●Identify the appropriate size of the ER wrench based on the collet nut size.

●Insert the hexagonal end of the ER wrench into the collet nut.

●Hold the wrench securely, ensuring a firm grip on the T-shaped handle.

●To tighten the collet, rotate the wrench clockwise until the collet nut is securely fastened.

●To loosen the collet, rotate the wrench counterclockwise until the collet nut is sufficiently loosened.

Remember to exercise caution while using the ER wrench, ensuring that it remains engaged with the collet nut throughout the tightening or loosening process. Find Out More.

The ER wrench is an essential tool for CNC machinists working with ER collets. Its comfortable grip, precise fit, durability, and ease of use make it an indispensable companion during tool changes and collet adjustments. By utilizing the ER wrench correctly, machinists can ensure the proper installation and secure tightening of ER collets, enhancing the overall precision and performance of the CNC machining process.