Grain Size: 0.6UM

HRC:45 & 55

Coating: No & DLC(high performance)

Helix Angle: 35

Flutes: 2

Application: Profession for Copper & Aluminum.

Product Tags:

carbide end mills, ball nose end mills, aluminum machining tools, cutting tools, precision engineering, metalworking equipment, industrial tools, titanium aluminum nitride coating, high-quality tools, durable end mills, aluminum milling, professional machining tools, hobbyist tools, craftsmanship, advanced machining techniques

Non-standard production & OEM are welcome anytime.

We are pleased to introduce our company's latest offering: Carbide Ball Nose End Mills specifically designed for aluminum machining applications. Our high-quality end mills are engineered to deliver exceptional performance, precision, and durability, enabling efficient and accurate machining of aluminum materials.

Carbide Ball Nose End Mills for Aluminum

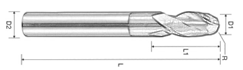

| Type | d | D | L1 | L | Flute |

| HRC55-AL2-R0.5*50 | 1 | 4 | 2 | 50 | 2 |

| HRC55-AL2-R0.75*50 | 1.5 | 4 | 3 | 50 | 2 |

| HRC55-AL2-R1*50 | 2 | 4 | 4 | 50 | 2 |

| HRC55-AL2-R1.25*50 | 2.5 | 4 | 5 | 50 | 2 |

| HRC55-AL2-R1.5*50*D3 | 3 | 3 | 6 | 50 | 2 |

| HRC55-AL2-R1.5*50 | 3 | 4 | 6 | 50 | 2 |

| HRC55-AL2-R1.75*50 | 3.5 | 4 | 7 | 50 | 2 |

| HRC55-AL2-R2*50 | 4 | 4 | 8 | 50 | 2 |

| HRC55-AL2-R2.5*50*D5 | 5 | 5 | 10 | 50 | 2 |

| HRC55-AL2-R2.5*50*D6 | 5 | 6 | 10 | 50 | 2 |

| HRC55-AL2-R3*50 | 6 | 6 | 12 | 50 | 2 |

| HRC55-AL2-R4*60 | 8 | 8 | 16 | 60 | 2 |

| HRC55-AL2-R5*75 | 10 | 10 | 20 | 75 | 2 |

| HRC55-AL2-R6*75 | 12 | 12 | 24 | 75 | 2 |

| HRC55-AL2-R7*100 | 14 | 14 | 28 | 100 | 2 |

| HRC55-AL2-R8*100 | 16 | 16 | 32 | 100 | 2 |

| HRC55-AL2-R9*100 | 18 | 18 | 36 | 100 | 2 |

| HRC55-AL2-R10*100 | 20 | 20 | 40 | 100 | 2 |

| HRC55-AL2-R2*75 | 4 | 4 | 8 | 75 | 2 |

| HRC55-AL2-R2*100 | 4 | 4 | 8 | 100 | 2 |

| HRC55-AL2-R3*75 | 6 | 6 | 12 | 75 | 2 |

| HRC55-AL2-R3*100 | 6 | 6 | 12 | 100 | 2 |

| HRC55-AL2-R3*150 | 6 | 6 | 12 | 150 | 2 |

| HRC55-AL2-R4*75 | 8 | 8 | 16 | 75 | 2 |

| HRC55-AL2-R4*100 | 8 | 8 | 16 | 100 | 2 |

| HRC55-AL2-R4*150 | 8 | 8 | 16 | 150 | 2 |

| HRC55-AL2-R5*100 | 10 | 10 | 20 | 100 | 2 |

| HRC55-AL2-R5*150 | 10 | 10 | 20 | 150 | 2 |

| HRC55-AL2-R6*100 | 12 | 12 | 24 | 100 | 2 |

| HRC55-AL2-R6*150 | 12 | 12 | 24 | 150 | 2 |

| HRC55-AL2-R7*150 | 14 | 14 | 28 | 150 | 2 |

| HRC55-AL2-R8*150 | 16 | 16 | 32 | 150 | 2 |

| HRC55-AL2-R10*150 | 20 | 20 | 40 | 150 | 2 |

◎Material: Our Carbide Ball Nose End Mills are crafted using premium-grade carbide materials, known for their exceptional hardness and wear resistance. This ensures extended tool life and reduced tooling costs.

◎Ball Nose Design: The ball nose design of our end mills allows for smooth and precise contouring, profiling, and finishing operations on aluminum materials. The rounded tip minimizes tool marks and provides excellent surface finishes.

◎Flute Geometry: The flute geometry of our end mills is optimized for aluminum machining. It ensures efficient chip evacuation, reducing the risk of chip clogging and material buildup, thereby enhancing productivity and surface quality.

◎Coating Options: Our Carbide Ball Nose End Mills come with a variety of coating options, such as TiCN, TiN, and AlTiN, to enhance tool life, reduce friction, and prevent aluminum adhesion, ensuring superior performance in demanding machining applications.

◎Shank Options: We offer a range of shank options, including straight shank and shank with Weldon flats, to accommodate various machine tool setups and provide excellent stability during machining operations.

◎Enhanced Efficiency: The exceptional cutting performance of our Carbide Ball Nose End Mills allows for increased machining speeds and feeds, resulting in higher productivity and reduced cycle times.

◎Precision Machining: The precise ball nose design enables accurate and intricate machining of complex aluminum profiles, contours, and cavities, ensuring dimensional accuracy and excellent surface finishes.

◎Extended Tool Life: The superior hardness and wear resistance of our carbide materials, combined with the advanced coatings, contribute to longer tool life, minimizing tool changeovers and reducing overall machining costs.

◎Versatility: Our end mills are suitable for a wide range of aluminum alloys, including pure aluminum, aluminum-copper alloys, and aluminum-silicon alloys, making them ideal for various industries such as automotive, aerospace, electronics, and more.

Our Carbide Ball Nose End Mills for Aluminum is specifically designed for the following applications:

◎Aluminum contouring, profiling, and finishing

◎Aluminum cavity machining

◎Aluminum pocketing and slotting

◎Aluminum mold and die machining

◎Aluminum component manufacturing

Our Carbide Ball Nose End Mills for Aluminum is available in a wide range of sizes, flute counts, and shank options to meet specific customer requirements. Please refer to our catalog or contact our sales team for detailed product information and availability.

A: These carbide ball nose end mills are specifically designed for aluminum machining, but they can also be used with other non-ferrous materials such as brass or copper.

A: Absolutely! Our precision end mills are suitable for both professional machinists and hobbyists. They provide exceptional performance and reliability for a wide range of aluminum machining projects.

A: Yes, we offer a variety of sizes to choose from. Please refer to our product options for specific diameter, shank diameter, and overall length measurements.

A: Our carbide ball nose end mills are coated with TiAlN (Titanium Aluminum Nitride), which enhances their durability and prolongs tool life.

Carbide Ball Nose End Mills for Aluminum offers exceptional performance, precision, and durability. With their specialized design and advanced features, these end mills enable efficient and accurate machining of aluminum materials, catering to a wide range of applications in various industries. Trust our end mills to elevate your aluminum machining capabilities and achieve superior results.