HRC55 Carbide Square End Mills

Coating: AlTiNGrain Size: 0.4UM

HRC: 55

Helix Angle: 35

Flutes: 2&4

Application: Copper, tool steel, quenched and tempered steel,

Carbon steel, cast iron, stainless steel, Heat treatment and quenching of steel.

Non-standard production & OEM is welcomed anytime.

HRC55 Carbide Square End Mills

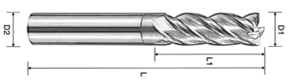

RuiHan HRC55 Tungsten Carbide End Mill is a leading tool for high-performance machining, renowned for its exceptional durability and precision. With dimensions up to 20mm, these end mills offer consistent performance and quality, catering to diverse industrial applications.

Tungsten carbide is an alloy created by sintering cemented carbide powder with iron-based metal powder. Its extreme hardness makes it a preferred choice for cutting tools, particularly the HRC55 Tungsten Carbide End Mill. Cutting edges come in various shapes, with two-flute and four-flute helical designs being the most commonly used.

Carbide end mills are designed to cut hard-to-machine materials. The "carbide" in HRC55 Tungsten Carbide End Mill refers to a sintered alloy with extremely high hardness. With a longitudinal modulus of elasticity three times that of iron and an indentation hardness of about 90, carbide end mills are unparalleled in precision cutting.

The RuiHan series of HRC55 Tungsten Carbide End Mills features high dimensional accuracy. This is achieved through proprietary in-house production machines and advanced measuring equipment, ensuring superior quality and reliability.

The innovative flute geometry, developed using RuiHan's custom grinding program, enhances cutting efficiency. Coupled with specialized coating films tailored for various materials, these tools deliver exceptional performance, including direct milling of tungsten carbide—previously considered impossible.

RuiHan provides both standard and custom carbide cutting tools. These solutions cater to:

Aviation aerospace industry

Medical industries

Automotive sectors (cars, motorcycles, bicycles)

Mold and mechanical parts

Metal special shape processing

Your specific requirements are the standard for our custom carbide cutting tools, including the HRC55 Tungsten Carbide End Mill.

| Type | d | D | L1 | L | Flute |

| HRC55-RH4-1*50 | 1 | 4 | 3 | 50 | 4 |

| HRC55-RH4-1.5*50 | 1.5 | 4 | 4 | 50 | 4 |

| HRC55-RH4-2*50 | 2 | 4 | 5 | 50 | 4 |

| HRC55-RH4-2.5*50 | 2.5 | 4 | 6 | 50 | 4 |

| HRC55-RH4-3*50*D3 | 3 | 3 | 8 | 50 | 4 |

| HRC55-RH4-3*50 | 3 | 4 | 8 | 50 | 4 |

| HRC55-RH4-3.5*50 | 3.5 | 4 | 9 | 50 | 4 |

| HRC55-RH4-4*50 | 4 | 4 | 10 | 50 | 4 |

| HRC55-RH4-5*50 | 5 | 5 | 13 | 50 | 4 |

| HRC55-RH4-5*50 | 5 | 6 | 13 | 50 | 4 |

| HRC55-RH4-6*50 | 6 | 6 | 15 | 50 | 4 |

| HRC55-RH4-8*60 | 8 | 8 | 20 | 60 | 4 |

| HRC55-RH4-10*75 | 10 | 10 | 25 | 75 | 4 |

| HRC55-RH4-12*75 | 12 | 12 | 30 | 75 | 4 |

| HRC55-RH4-14*100 | 14 | 14 | 45 | 100 | 4 |

| HRC55-RH4-16*100 | 16 | 16 | 45 | 100 | 4 |

| HRC55-RH4-18*100 | 18 | 18 | 45 | 100 | 4 |

| HRC55-RH4-20*100 | 20 | 20 | 45 | 100 | 4 |

| HRC55-RH4-4*75 | 4 | 4 | 16 | 75 | 4 |

| HRC55-RH4-4*100 | 4 | 4 | 20 | 100 | 4 |

| HRC55-RH4-6*75 | 6 | 6 | 18 | 75 | 4 |

| HRC55-RH4-6*100 | 6 | 6 | 30 | 100 | 4 |

| HRC55-RH4-6*150 | 6 | 6 | 45 | 150 | 4 |

| HRC55-RH4-8*75 | 8 | 8 | 25 | 75 | 4 |

| HRC55-RH4-8*100 | 8 | 8 | 35 | 100 | 4 |

| HRC55-RH4-8*150 | 8 | 8 | 50 | 150 | 4 |

| HRC55-RH4-10*100 | 10 | 10 | 40 | 100 | 4 |

| HRC55-RH4-10*150 | 10 | 10 | 55 | 150 | 4 |

| HRC55-RH4-12*100 | 12 | 12 | 45 | 100 | 4 |

| HRC55-RH4-12*150 | 12 | 12 | 55 | 150 | 4 |

| HRC55-RH4-14*150 | 14 | 14 | 60 | 150 | 4 |

| HRC55-RH4-16*150 | 16 | 16 | 70 | 150 | 4 |

| HRC55-RH4-20*150 | 20 | 20 | 70 | 150 | 4 |

High-Speed Cutting: The extreme hardness of carbide allows for faster cutting than high-speed steel (HSS), reducing machining time.

Rigidity and Stiffness: These properties prevent bending and shaft expansion, ensuring accurate machining.

Strength Loss: Compared to HSS, carbide end mills are less resistant to strength loss, which can lead to surface defects on inserts.

To achieve optimal results, it is crucial to select the proper machining process based on factors such as the diameter and type of carbide end mill and the material being cut. Our 6mm End Mill Cutter is an excellent example of a precision tool for intricate applications. As a trusted Long End Mill Supplier, we provide a wide range of carbide end mills tailored to meet diverse industry needs. Our focus is on delivering high-quality tools, including the HRC55 Tungsten Carbide End Mill, ensuring efficiency and precision in every application.

RuiHan Tungsten Carbide End Mill offers unparalleled cutting performance, making it an indispensable tool for professionals in various industries. From its exceptional hardness to its cost-effectiveness, this tool represents the pinnacle of innovation in cutting technology. Contact us now to get assistance from our team of skilled professionals!