DIN6341 Collet

Draw in collets according to DIN 6341 (Series 300) with smooth clamping bore. Collet type B8, K12 collets, collets B15, collets W20, collet K20, draw-in collet L20, B23 collets, collets K23, B25 collets, W25 collets, collets 366E, K28 collets, 5C draw-in collets, K32 collets for clamping workpieces in indexing devices, grinding machines and milling machines, or second-operation lathes or rotary indexing turning machines.

RuiHan Draw-In Collet Chuck is a critical tool in high-precision machining, designed to securely hold workpieces and cutting tools. With a focus on stability, accuracy, and flexibility, this collet chuck is ideal for applications requiring exact tool alignment, minimal runout, and rigid tool holding. As a specialized toolholding device, the Draw-In Collet Chuck is particularly useful for high-precision machining in industries such as aerospace, medical device manufacturing, and mold making.

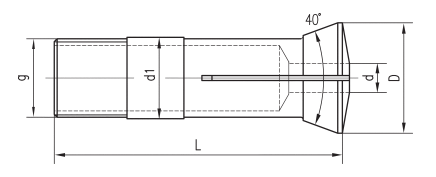

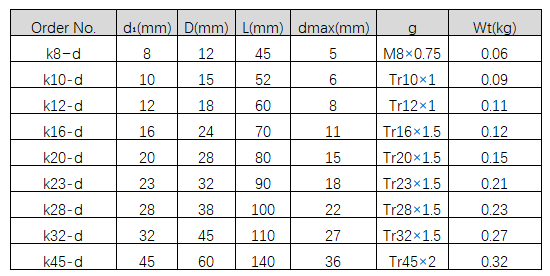

Our Draw-In Collet Chuck is crafted with precise dimensions to ensure optimal functionality and reliability. The main specifications include:

| Name | DIN6341 Collet |

| Material | 65Mn |

| Hardness | HRC44-48 |

| Outer Diameter | 28 mm |

| Diameter | 20 mm |

| Length | 117.5 mm |

| Thread Dimension | SG 20 x 2 |

| Profile Shape | Round and smooth |

| Designation | DIN 6341 355 E |

| Alpha Angle | 17° 30' |

In the machining industry, the Draw-In Collet Chuck is compatible with several collet types, including DIN 6341 Collet and ER Collets. Here’s a detailed comparison of these collet types to highlight their unique features and applications.

Standard: Built to meet the DIN 6343 standard.

Shape: Cylindrical with slits for flexibility, ideal for a draw-in clamping mechanism.

Closing Mechanism: Utilizes a drawbar to secure the collet, providing rigid clamping for precision applications.

Standard: Conforms to the DIN 6499 standard.

Shape: Tapered design with multiple slots for a self-centering, flexible hold.

Closing Mechanism: Tightens with a nut, enabling even clamping pressure throughout.

Clamping Range: Narrower, offering a more rigid hold with minimal runout.

Applications: Best suited for high-precision tasks where exact alignment is essential, such as grinding.

Clamping Range: Wider clamping flexibility, accommodating a 1 mm variation in tool diameter.

Applications: Well-suited for general-purpose machining, allowing versatility across various tasks.

The Draw-In Collet Chuck offers significant advantages in tool holding and runout control:

Tool Holding: Provides a rigid grip, ideal for applications where stability is crucial.

Runout: Minimal runout, ensuring high precision in sensitive machining tasks.

Tool Holding: While slightly more flexible, it provides acceptable holding for most general machining tasks.

Runout: Slightly higher than DIN collets but designed for self-centering to maintain precision.

Cost: Generally more expensive due to their rigid construction and precision focus.

Availability: Available through specialized suppliers, often tailored to industries requiring tight tolerances.

Cost: More affordable, providing cost-effective solutions for a variety of machining needs.

Availability: Widely available, making them an accessible choice for general-purpose use.

The Draw-In Collet Chuck has diverse applications across precision industries. With the ability to use both DIN 6341 Collet and ER Collets, it can perform effectively in:

High-Precision Machining: Essential in industries requiring tight tolerances, such as aerospace and medical device manufacturing.

General-Purpose Machining: Adaptable with ER collets for a variety of tasks, offering versatility and flexibility.

Specialized Applications: When paired with the Taper Collet K32 or Hydraulic Collet, this chuck provides reliable performance in high-stress machining conditions.

The Draw-In Collet Chuck is an indispensable tool for high-precision machining, making it highly versatile. Additionally, for specialized applications, it can integrate with Taper Collet K32 and Hydraulic Collet options, providing a customized approach for specific machining needs. RuiHan Colletstands as a top choice for machining professionals, providing stability, precision, and versatility. Whether paired with DIN 6341 Collet for high-precision tasks or Taper Collet K32 for specialized applications, this tool offers unmatched performance, making it a valuable asset in any machining environment. Inquire now to experience our incomparable carbide cutting tools!