Value-priced collet chucks with a selection of collets for holding tools with cylindrical shafts. End mills, drills, countersinks, or even thread cutters can be gripped with high precision.

Product parameters:

● Material: 65Mn

● Hardness: HRC44-48

● Runout: 0.01-0.015mm

Product Features:

● High grip strength

● Excellent tool retention

● Good high-speed performance

● Excellent damping

● For machining center and milling machine.

Milling Chuck Collets are essential tools in machining, designed to securely hold and stabilize workpieces during the milling process. Engineered for precision and reliability, they ensure stability and accuracy in both CNC and manual milling operations. A collet is a cylindrical sleeve, typically made of spring steel, designed to form a collar around a tool or workpiece. It provides uniform clamping pressure, maintaining the central position of the tool during rotation. Collets are integral to achieving stable and accurate machining results.

Milling chucks are versatile, high-accuracy tool holders with very high gripping power and very low runout. They are great for heavy milling applications, and for holding larger diameter tool shanks. The solid one-piece construction and symmetrical design of the tool holder provide high accuracy and good balance characteristics.

RuiHan milling chucks are designed to hold a single-size tool shank, and then precision straight-shank reducing collets are used to hold smaller-diameter tools. The straight collet design provides even clamping along the entire length of the shank, eliminating axial movement of the tool, increasing rigidity, and minimizing runout. This results in better surface finishes and longer tool life, as well as high gripping force for heavy milling.

Simple twist-lock operation and high retention force make these milling chucks ideal for general-purpose operations. Whether you are engaged in high-precision CNC milling or manual milling operations, our Milling Chuck Collets offer the reliability and performance you need to achieve superior machining results. Trust in our expertly crafted collets to enhance your milling processes and deliver exceptional quality and efficiency.

Key Features of RuiHan Milling Chuck Collets

High Clamping Force: Delivers exceptional gripping power to prevent tool slippage during operation.

Precision Engineering: Reduces runout and ensures consistent tool positioning, improving machining accuracy.

Durable Construction: Made from premium materials for long-lasting performance under rigorous conditions.

Versatile Compatibility: Compatible with a wide range of milling machines and toolholders.

Ease of Use: Simple twist-lock mechanism enables quick installation and removal, minimizing downtime.

Product Parameters

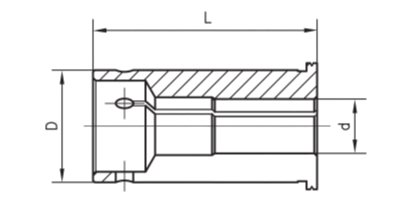

Model No. | D(mm) | d(mm) | L(mm) |

C16 | 16 | 4-12 | 45 |

C20 | 20 | 4-16 | 50 |

C22 | 22 | 4-16 | 55 |

C25 | 25 | 4-20 | 60 |

C32 | 32 | 4-25 | 65 |

C40 | 40 | 6-32 | 80 |

C42 | 42 | 6-32 | 80 |

In addition to their secure grip, Milling Chuck Collets also offer excellent precision and accuracy. This is crucial for achieving precise cuts and maintaining tight tolerances during the milling process. Whether you're working with metal, plastic, or other materials, these collets are an essential tool for any machinist or engineer. Contact us to customize your milling chuck.

Types of Milling Chucks RuiHan Can Provide

Collet Chucks

Collet chucks are perfect for securing small-diameter tools such as drills, reamers, and end mills. They ensure exceptional accuracy and high clamping force, making them indispensable for precision milling tasks.

Power Chucks

Designed for heavy-duty applications, power chucks use hydraulic or pneumatic pressure to secure larger tools. They are ideal for machining operations that require robust clamping and high accuracy.

Hydraulic Chucks

Hydraulic chucks provide excellent rigidity and vibration dampening, making them suitable for high-speed machining. They deliver exceptional accuracy and are compatible with a range of tools.

Drill Chucks

Drill chucks feature a three-jaw design for securely holding drill bits. They are widely used for deep drilling operations due to their quick and efficient tool change capabilities.

Pneumatic Chucks

Pneumatic chucks use compressed air to clamp tools, offering fast clamping and release. They are highly accurate and ideal for high-speed machining applications.

Applications of Milling Chuck Collets

Milling Chuck Collets are versatile and find applications in various industries, including:

Woodworking: Used in drill presses for holding router bits securely.

Metalworking: Commonly used to secure tools like round bars, square collets, and hexagonal collets.

CNC Machining: ER collets, ranging from ER-8 to ER-50, are widely used for precision clamping in CNC mills.

Automotive Industry: Employed in engine mechanisms to maintain consistent pressure on components.

Semiconductor Manufacturing: Used for delicate and precise clamping tasks.

Selecting the appropriate Collet Chuck for Milling Machine is essential for achieving optimal results. Consider the following factors:

Material Being Machined: Ensure the collet can withstand the forces involved in cutting hard or brittle materials.

Part Size and Shape: Match the collet type to the size and shape of the workpiece for secure clamping.

Cutting Forces: Choose collets designed for high clamping force to handle heavy-duty machining.

Tool Holder Compatibility: Verify that the collet matches the toolholder specifications.

Speeds and Feeds: Opt for collets with dampening properties for high-speed operations or strong clamping for slower speeds.

Ruihan is your easy one-stop source for all things metalworking, and we’re positive we can help you find the perfect quality solutions for all your machine shop needs. Milling Chuck Collets are a reliable and effective solution for holding and securing workpieces during the milling process. With their secure grip, precision, and ease of use, they are an essential tool for anyone involved in milling operations. For assistance with finding the right tools or any other questions, please feel free to our customer support team now.