Material:65Mn

Hardness: HRC44-48

Runout: 0.01-0.015mm

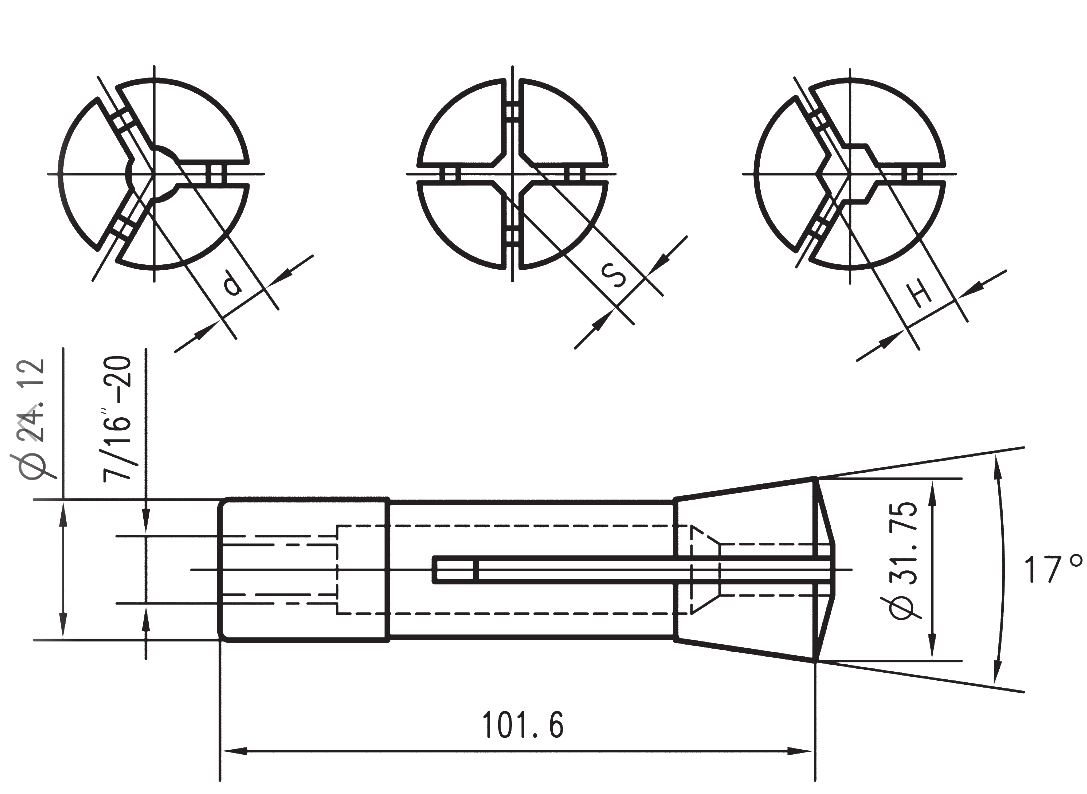

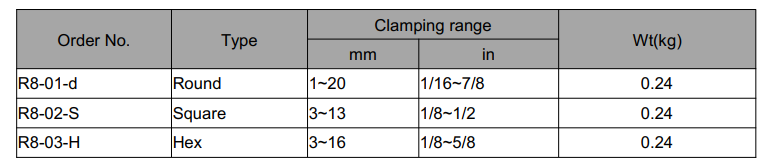

R8 Collet to securely hold round-shank tool bits in the R8 spindle of a milling machine. They have internal threads.

RUIHAN TOOLS- Quality Collets Manufacturers and Exporters in China

An R8 collet is a specialized clamping device used in machining and milling. It is designed to hold workpieces securely in place, allowing for precise cutting, shaping, and drilling operations. The “R8” designation refers to the taper size of the collet, which is commonly found on milling machines.

The R8 collet is manufactured to exacting standards from special alloy steel. All R8 collets have a solid one-piece design, hardened and spring-tempered to ensure accuracy and durability. Precision R8 Collets for manual and CNC milling machines are carburized and case-hardened for maximum wearability and strength. They are harder than any other R8 collet on the market. A custom process is used to eliminate the use of bushings for the internal draw threads.

● Precision grade R8 collets

● Hardened and ground

● Inch or metric collet tool sizes

● Reduces tool change time

● High-grade steel for long wear life

● Can be used with most R8 collet fixtures

● Kits available

One of the key advantages of using an R8 collet is its exceptional gripping power. The design of the collet allows for a tight and secure grip on the tool shank, ensuring minimal movement or slippage during operation. This translates into greater accuracy and precision in your machining work.

Additionally, R8 collets are known for their versatility. They can accommodate various tool sizes within their specified range, making them suitable for different applications. Whether you’re working with end mills, drill bits, reamers, or other tools commonly used in machining and milling processes, an R8 collet can handle them all with ease.

Another benefit worth mentioning is the quick change capability offered by R8 collets. With just a simple twist or release mechanism, you can quickly swap out tools without wasting precious time on complex setups or adjustments.

Moreover, durability is another advantage associated with using an R8 collet. Made from high-quality materials such as hardened steel or carbide-tipped variants, these collets are designed to withstand heavy-duty use over extended periods without compromising performance.

Lastly, yet importantly, the compatibility factor cannot be overlooked when discussing the advantages of using an R8 collet. These types of collets are widely compatible across different machines and models that utilize this standard-size format, collecting widespread praise throughout various workshops globally.

R8 Collets offer numerous benefits that contribute to improved efficiency, reliability, and accuracy in machining work. With their superior gripping power, durability, and versatility, it’s no wonder why they have become such a popular choice among professionals in the field. Get a quick quote!

An R8 collet is a specialized clamping device used in machining and milling. It is designed to hold workpieces securely in place, allowing for precise cutting, shaping, and drilling operations. The “R8” designation refers to the taper size of the collet, which is commonly found on milling machines.

Made from high-quality materials such as hardened steel or carbide, R8 collets are known for their durability and strength. They feature a unique internal shape that allows them to grip tightly onto round workpieces with minimal slippage.

One of the distinguishing features of an R8 collet is its ability to be quickly changed out within the spindle of a milling machine. This makes it incredibly convenient when working on multiple projects or switching between different tooling setups.

To ensure proper usage, it’s important to understand how an R8 collet operates. When inserted into the machine’s spindle, a drawbar mechanism tightens the collet around the workpiece by pulling it upwards against tapered surfaces. This creates a secure grip that prevents any movement during machining processes.

An R8 collet plays a vital role in achieving precision and accuracy in machining and milling applications. Its versatility and ease of use make it a go-to choice for many professionals in various industries where precise clamping is crucial.

R8 Collets in round sizes are 1/16" to 7/8" in 1/32" increments, or 3mm to 22mm in 1mm increments.

R8 collets have a keyway to prevent rotation when fitting or removing, but it is the compressed taper and not the keyway that provides the driving force. Collets are compressed by a drawbar from behind, they are self-releasing and tool changes can be automated.

R8 taper shank ER collet chucks are typically used. manual milling machines. The R8 taper end fits into a. machine spindle and the ER collet nut is compatible. with ER collet.

The standard R8 Collet is 20mm while the extending R8 Collet is 25mm.

1. Size: The size of the collet should match the diameter of the tool you will be using. Ensure that you have a range of sizes available to accommodate different tools.

2. Material: Consider the material of the collet based on your application requirements. Some materials offer better durability and heat resistance, while others may provide improved gripping power.

3. Tolerance: Pay attention to the tolerance level of the collet, as this affects its ability to securely hold tools within specified limits.

4. Brand reputation: Choose a reputable brand known for manufacturing high-quality R8 collets that meet industry standards.

5. Compatibility: Verify that the chosen collet is compatible with your milling machine or lathe spindle taper type (such as R8).

6. Price: While cost shouldn’t be the sole determining factor, consider your budget for quality and features offered by various brands.

By considering these factors, you can select an R8 collet that meets your specific machining and milling needs, ensuring efficient operation and superior results without compromising safety or performance. The R8 collet is a versatile and essential tool in machining and milling applications. Its ability to securely hold tools in place while providing excellent accuracy and precision makes it a popular choice among professionals. So whether you’re a professional machinist or a hobbyist looking to upgrade your equipment, don’t overlook the importance of an R8 collet in ensuring successful machining operations!