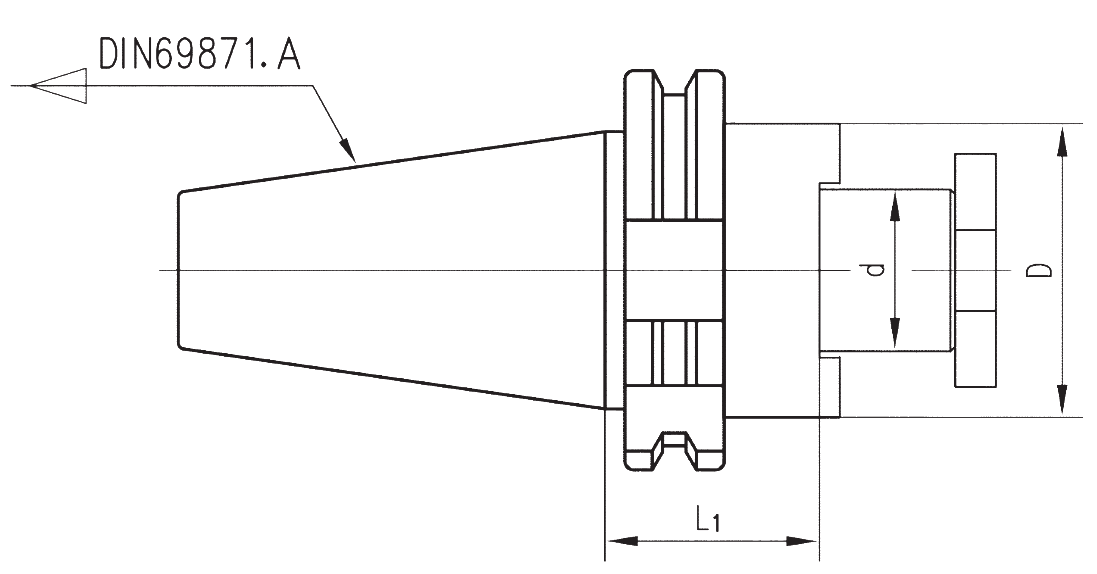

DIN69871 Face Mill Arbor including:

Form AD, AD/B balanced G6.3 15000rpm and G2.5 25000rpm

The DIN69871 Face Mill Arbor is a specialized cutting tool holder that is designed to securely hold and drive face milling cutters for precision machining operations. It conforms to the DIN 69871 standard, which is widely recognized and used in the metalworking industry. The DIN69871 Face Mill Arbor is designed to provide high-speed, high-torque cutting performance, allowing for efficient and precise material removal, resulting in superior surface finishes and increased productivity.

The Face Mill Arbor is a versatile cutting tool that is designed to securely hold and drive face milling cutters for precision machining operations. It is a critical component in the manufacturing process for a wide range of industries, including aerospace, automotive, and heavy machinery, among others. The Face Mill Arbor is engineered to provide high-speed, high-torque cutting performance, allowing for efficient and accurate material removal, resulting in superior surface finishes and increased productivity.

Milling arbors belong to the standard equipment of milling machines and are used to mount milling cutters: cylindrical, disc, circular, angular and other.

The Face Mill Arbor offers a reliable and efficient solution for holding and driving face milling cutters, ensuring precise and accurate machining operations. With its high-quality construction, precision design, and versatile compatibility, the Face Mill Arbor delivers superior performance, increased productivity, and cost-effective machining solutions for businesses seeking to optimize their manufacturing processes.

Jinan Ruihan Imp&Exp Co.,Ltd is professional manufacturer of CNC Machine tools & Machinery with 20 years experience.Ruihan's collets, toolholders, milling cutters, turning tools have a long-term stable output in many countries.

◆High-quality construction: The Face Mill Arbor is made from high-grade materials, such as hardened steel, to ensure durability and long-lasting performance in demanding machining environments.

◆Precision design: The Face Mill Arbor features a precise design that allows for easy and accurate mounting of face milling cutters, ensuring minimal runout and maximum cutting performance.

◆Versatile compatibility: The Face Mill Arbor is designed to be compatible with a wide range of face milling cutters, making it suitable for various machining applications, including roughing, finishing, and profiling.

◆Enhanced safety: The Face Mill Arbor incorporates safety features, such as a secure clamping mechanism and anti-rotation design, to prevent cutter slippage or ejection during operation, ensuring operator safety.

◆Easy to use: The Face Mill Arbor is designed for easy installation and removal, reducing downtime and increasing productivity in machining operations.

◆Cost-effective: The Face Mill Arbor provides a cost-effective solution for machining operations, as it enables efficient material removal, reducing production time and costs.

The Face Mill Arbor is an essential cutting tool for precision machining operations, offering durability, precision, and versatility. Its high-quality construction, precision design, and safety features make it a reliable choice for machining applications in various industries. By providing efficient material removal, improved surface finishes, and increased productivity, the Face Mill Arbor is a valuable addition to any machining operation, delivering outstanding results and enhancing overall manufacturing performance.

1.Metalworking: The Face Mill Arbor is widely used in metalworking operations, such as milling, contouring, and profiling of ferrous and non-ferrous materials. It is used for both roughing and finishing operations to achieve precise and accurate results in applications such as automotive parts manufacturing, aerospace components, and general engineering.

2.Aerospace: The aerospace industry demands high-precision machining for critical components that require tight tolerances and superior surface finishes. The Face Mill Arbor is commonly used for machining aerospace components, including structural parts, engine components, and landing gear components.

3.Automotive: The automotive industry relies on the Face Mill Arbor for machining various automotive parts, such as engine blocks, cylinder heads, transmission components, and suspension components. The precision cutting performance of the Face Mill Arbor ensures accurate machining of these parts, meeting the stringent requirements of the automotive industry.

4.Energy: The energy industry, including oil and gas, power generation, and renewable energy, requires precision machining for components such as turbine blades, gearboxes, and casings. The Face Mill Arbor is used for machining these components, ensuring high-quality and efficient production.

5.General Engineering: The Face Mill Arbor is widely used in general engineering applications, where precision machining is required for producing components used in diverse industries, including agriculture, construction, and heavy machinery. It is used for milling and profiling operations, producing accurate and consistent results.

6.Die and Mold Making: The Face Mill Arbor is commonly used in die and mold making applications for machining complex shapes, contours, and profiles. It allows for efficient material removal and superior surface finishes, making it a valuable tool in producing high-quality dies and molds for various industries.

In summary, the Face Mill Arbor is a versatile cutting tool that is widely used in precision machining applications across multiple industries, including metalworking, aerospace, automotive, energy, general engineering, and die and mold making. Its high-speed, high-torque cutting performance, precise design, and versatility make it an essential tool for achieving accurate and efficient machining operations.

Click here to learn more about the brand story.