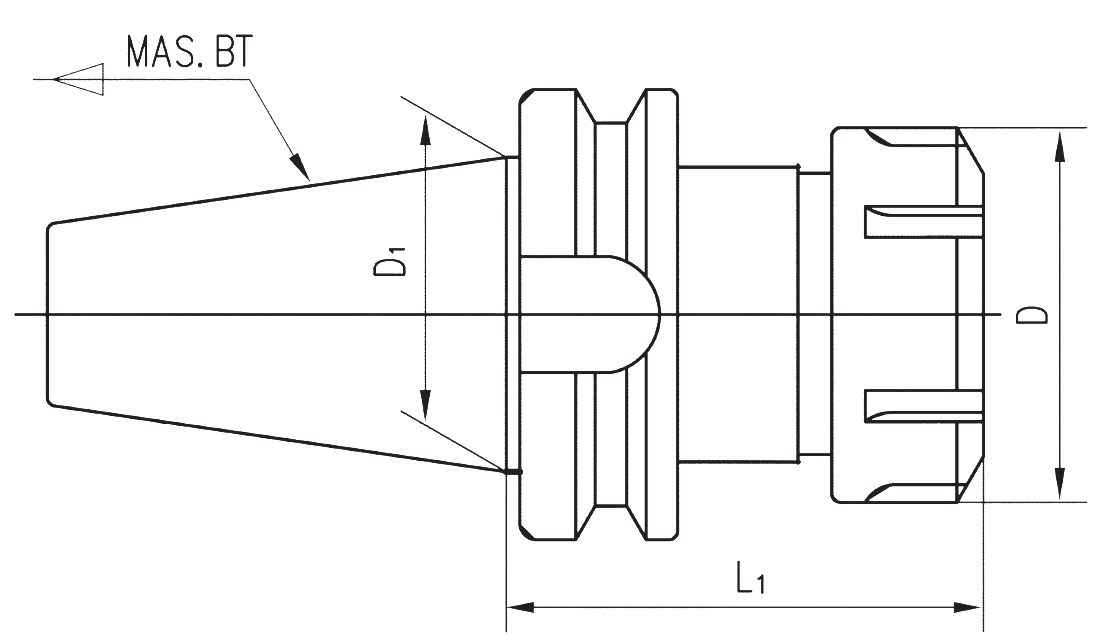

BT ER collet chuck is a better choice for drilling and lighter higher speed milling. It has two forms, Namely form AD and AD/B.

Both AD and AD/B have standard balances G6.3 15000rpm and G2.5 25000rpm.

The BT ER Collet Chuck series offers a comprehensive range of tool holders designed to optimize machining operations. With a variety of models available, including BT30 ER20, BT30 ER40, BT40 ER16, BT40 ER20, and BT40 ER40, we provide versatile solutions to meet the diverse needs of machining professionals.

The versatile design of ER collet chucks provides a wide range of machining options. Simply select the right ER collet and ER nut combination from our range.

○Taper BT30,BT40,BT50

○Hardness: HRC52-58

○Balanced G6.3 15000rpm or G2.5 25000rpm

○Material :40Cr or 20CrMnTi

A BT ER Collet Chuck is a type of tool holder used in machining centers, typically for milling operations. It consists of a collet chuck body that is designed to accept ER collets, which are used to hold various types of cutting tools, such as drills, end mills, reamers, and taps.

The BT in BT ER Collet Chuck stands for "Berg Taper," which is a standardized spindle taper commonly used in Japan. The taper is cone-shaped, with a metric thread for easy mounting and removal. ER refers to the type of collet used, which is a spring collet that can be tightened around the shank of a tool for a secure, concentric grip.

BT ER Collet Chucks are commonly used in high-speed machining applications where accuracy, rigidity, and efficient tool changes are important. They are suitable for use with various types of machining centers, including horizontal and vertical milling machines.

When using a BT ER Collet Chuck, it's essential to ensure that the spindle, collet, and cutting tool are clean and free from damage, as any contamination or imperfection can affect accuracy and performance. It's also essential to use the correct torque and tightening sequence when installing the collet and cutting tool to ensure proper clamping force and concentricity.

Key Features of BT ER Collet Chuck:

Superior Taper Design: Crafted with precision, our collet chucks feature the popular BT taper design, ensuring excellent tool stability and accuracy during high-speed machining. The BT taper enhances rigidity, minimizes runout, and maximizes torque transmission, resulting in superior cutting performance.

Secure Collet Clamping: The ER collet system is renowned for its exceptional clamping force and gripping capabilities. With our BT ER Collet Chucks, you can effortlessly secure a wide range of cutting tools, thanks to the reliable collet sizes available. Whether it's the BT30 ER20, BT30 ER40, BT40 ER16, BT40 ER20, or BT40 ER40 model, you can trust in the firm grip and precise tool positioning for consistent machining results.

Versatility and Compatibility: Our BT ER Collet Chucks are compatible with a variety of milling machines and machining centers, making them a versatile choice for various applications. The interchangeable collet sizes provide flexibility, allowing you to easily adapt to different tool diameters and achieve optimal performance in a wide range of machining tasks.

Enhanced Machining Efficiency: By utilizing our BT ER Collet Chucks, you can significantly enhance machining efficiency. The robust design and reliable clamping mechanism ensure minimal tool deflection and improved cutting stability, resulting in enhanced precision, surface finish, and overall productivity.

Durable and Reliable Construction: We prioritize quality and durability in every aspect of our BT ER Collet Chucks. Each tool holder is meticulously manufactured using high-quality materials and undergoes rigorous quality control measures to meet industry standards. This ensures long-lasting performance, minimizing downtime and maintenance costs.

Upgrade your machining capabilities with the BT ER Collet Chuck collection, featuring the BT30 ER20, BT30 ER40, BT40 ER16, BT40 ER20, and BT40 ER40 models. Experience the advantages of precise tool holding, versatility, and improved machining efficiency. Trust in our commitment to delivering high-quality tooling solutions that empower your machining operations. Get a Free Quotation.

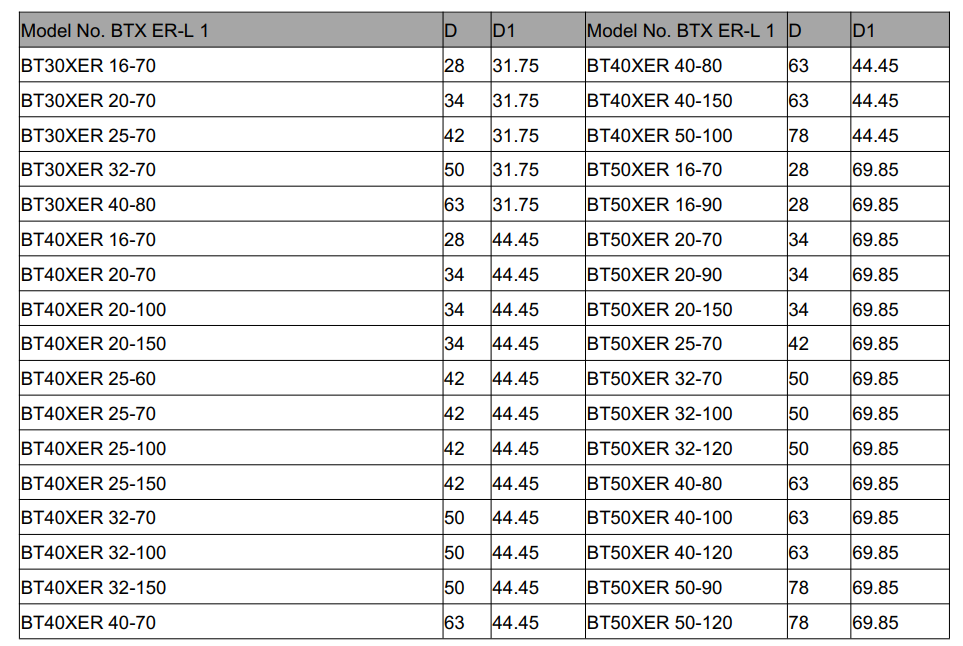

Here's a more detailed table comparing the differences between the BT30ER20, BT30ER40, BT40ER16, BT40ER20, and BT40ER40:

| Model | Taper Size (BT) | Collet Size (ER) | Nut Size (ER) | Maximum Collet Capacity |

| BT30ER20 | BT30 | ER20 | M12x0.75 | 13mm |

| BT30ER40 | BT30 | ER40 | M16x0.75 | 26mm |

| BT40ER16 | BT40 | ER16 | M10x0.75 | 10mm |

| BT40ER20 | BT40 | ER20 | M12x0.75 | 13mm |

| BT40ER40 | BT40 | ER40 | M16x0.75 | 26mm |

The table provides a detailed comparison of the different models, including the taper size (BT), collet size (ER), nut size (ER), and maximum collet capacity. This information helps you understand the specific characteristics and capabilities of each model, allowing you to make an informed decision based on your requirements and preferences.