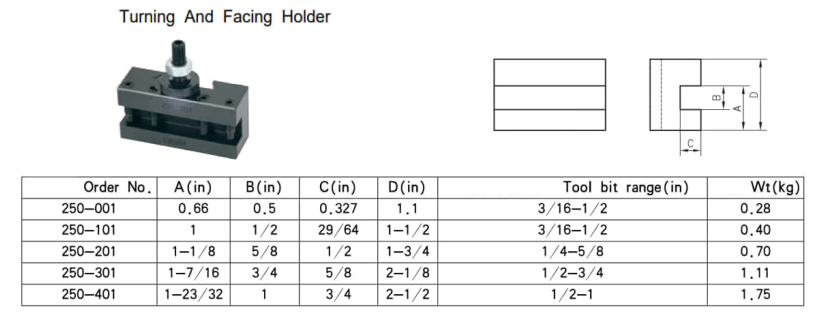

RuiHan Quick Change Tool Post Turning And Facing Holder

250-001 250-101 250-201 250-301 250-401

The tool holder is a very important part of the CNC lathe. CNC lathe according to its function, the tool holder can be installed on the number of tools - generally 4, 6, 8, 10 12, 20, 24, some CNC lathes can be installed more tools.

As a trusted Turning and Facing Holder Manufacturer, RuiHan designs high-quality tool holders that enhance rigidity, accuracy, and performance in turning, facing, and threading applications. Our holders are designed to fit seamlessly with 250 Quick Change Tool Post systems, supporting square shank tools for maximized stability. The robust construction and adaptability of these holders make them essential for high-precision work in various lathe setups.

Our turning and facing holders stand out for their performance-driven features, ensuring a secure and versatile experience for machinists and engineers.

Steel Construction: Our holders are constructed entirely from steel, offering superior mass and rigidity compared to aluminum alternatives.

Carbide Insert Compatibility: Designed to fit standard triangular positive rake carbide inserts, supporting both right-hand and left-hand operations.

Carbide Chipbreaker and Shim Protection: Each holder is equipped with fully adjustable carbide chipbreakers and shims, adding durability and protecting the tool from wear.

Quick Adjustment Mechanism: Compatible with 250 Quick Change Tool Post systems, our holders allow for rapid tool changes and easy height adjustments.

By securing square shank tool holders close to the tool post, our Turning and Facing Holder Manufacturer design maximizes rigidity, reducing vibration and allowing for more precise cuts. This rigidity is particularly beneficial when using high-quality Lathe Turret Tool Holders for demanding tasks.

Our tool holders are engineered to accommodate various turning, facing, and threading requirements, making them versatile for a range of CNC and manual lathe machines. Additionally, our universal design supports compatibility with AXA / 100 Series Quick Change Tool Posts, ensuring ease of use across multiple lathe brands.

To achieve optimal performance in face turning, our Turning and Facing Holder Manufacturer recommends following these guidelines:

Align the Tool Tip: Ensure the tool tip aligns with the center of the workpiece to avoid leaving a nub at the end face's center.

Select Back Draft Appropriately: For rough turning, use a back draft (ap) of 0.5–3 mm, while fine turning should use an ap of 0.05–0.2 mm.

Check Tool Stability: When turning larger diameters, check the tool holder and lock the tool post to ensure stable, precise lateral feeding.

Adjust the Feed Direction for Finishing: For high-quality finishes, conduct the final pass from the center outward.

As a reputable Turning and Facing Holder Manufacturer, we combine advanced design, durable materials, and comprehensive functionality. Our holders ensure:

Increased Productivity: Reduce setup time with quick-change compatibility.

Precision Engineering: Achieve higher accuracy in turning and facing applications.

Long-Term Reliability: With steel construction and protective chipbreakers, our holders are built to last.

As a leading Turning and Facing Holder Manufacturer, RuiHan provides holders compatible with CNC lathes designed to hold multiple tools for efficient machining. Our designs can accommodate a wide range of tools, including axial turning tools, radial turning tools, drills, and boring tools. For more advanced CNC setups, our holders support both radial and axial milling cutters, expanding the machining capabilities. Trust our expertise as your Turning and Facing Holder Manufacturer. With compatible designs for 250 Quick Change Tool Post and Lathe Turret Tool Holders, our solutions support your precision machining needs, enhancing accuracy and efficiency for professionals worldwide.

Quick Change Tool Posts

If this number is not provided on your lathe or in its manual, it can be determined by doubling the measured distance from the center of the spindle to the top of the closest way. For example, if you measure 6″, then you have a 12″ lathe swing